On the vegetable fields of Solawi-Bodensee there are – besides vegetables – also greenhouses, insect willows, Hügelkulturs, key and Indian beds, shelter for different animals, rain water cisterns, manures, a huge herb garden and much more. In order to explain all of these things, we created wooden signs.

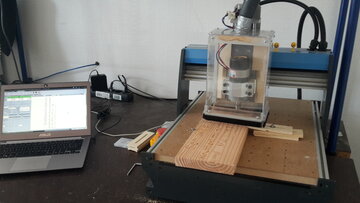

16 large and 17 small signs were milled with our Colinbus milling machine. The text is a line printing that can be milled with a 1/8" milling cutter and a depth of 2 mm in a relatively short time.

The prepared texts were separated into individual text files per sign where the first line is a header followed by 7 lines of explanatory text. Afterwards, we created SVG files with Inkscape and the Hershey Text plug-in via bash script. These were loaded with Easel and converted into NC files (g-code) which were then milled with bCNC.

Challenges

- File names must not contain umlauts or spaces

- Easel cannot load SVG files that contain groups

- Wood is not perfectly even

Example for a text file

Permaculture

An economy that

recreates natural ecosystems.

By using different

structures, we try to make

the conditions as ideal as

possible for their growth

and development.

Generating script

The script needs an SVG file as template in which the x-positions of the texts are defined and the header text has the ID textHeading. In addition, a thumbnail is created.

The script and the SVG templates can be found in Gitlab under Solawi Signs - German.

Settings in Easel

- Work surface: Birch Plywood (still works for the wood used), 135x380x12,7 mm

- Tool: End Mills > Straight cut > 1/2 in Double Flute Straight End Mill

- Cut settings: Depth per pass: 1 mm, keep the other setting as recommended

Create g-code in Easel

- Import SVG

- Set to 2 mm depth

- Machine > Advanced Settings

- Generate g-code

- Export g-code

- Rename file in file system

Process in bCNC

python -m bCNC

File

- Serial interface > Open

- File > Open

Control

- Reference run

- Move both X and Y 1 step away from home position (right and top), otherwise the limit switches will be activated again

- Clamp in wood

- Keep 5 mm distance from left and front edge as the g-code is generated without margin in order to use the whole area

- Move Y down to the wood and check with a piece of paper when the milling cutter is positioned directly above the wood

- Root: XYZ=0

- Move a few millimeters upwards

- Sept spindle to 7500 (in bCNC to 5000) rotations

- Connect vacuum cleaner and turn it on

- Turn on spindle

- Run > Start